Industrial Coffee Mill Guide: Increase Efficiency and Top Quality

In the competitive landscape of coffee manufacturing, selecting the right commercial coffee mill plays a crucial duty in boosting both performance and item quality. Recognizing the subtleties of numerous mill types and key functions-- such as adjustable grind settings and durable building-- can dramatically affect the final flavor account of the coffee. In addition, the optimization of the grinding process, combined with persistent maintenance, is necessary for sustaining efficiency gradually. As we explore these essential aspects, it becomes noticeable that the effects expand past plain tools selection, affecting total service success in manner ins which call for closer examination.

Understanding Mill Kinds

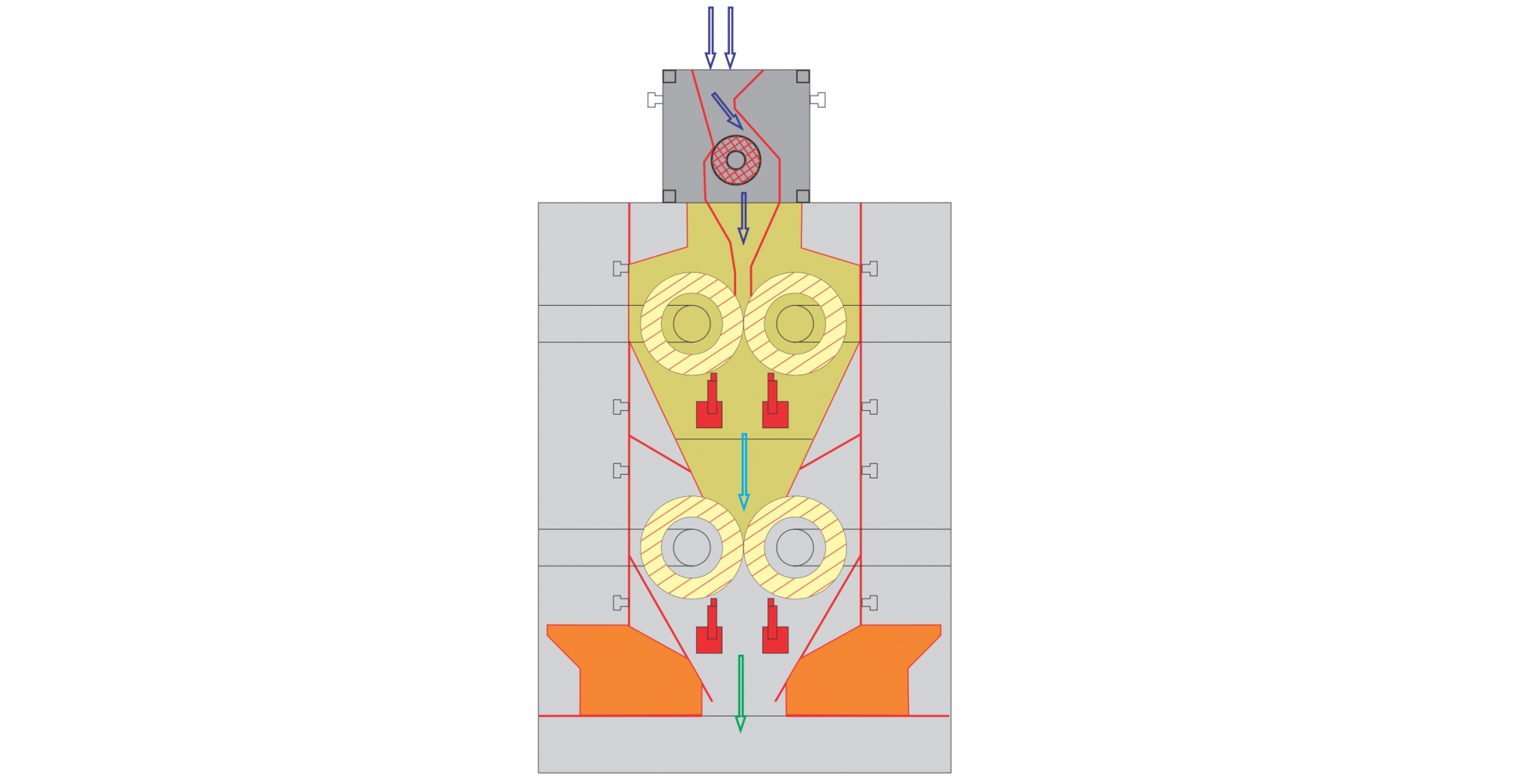

When choosing a commercial coffee mill, recognizing the various types readily available is vital for enhancing both taste extraction and operational efficiency. The two key kinds of mills are blade grinders and burr mills.

Eventually, choosing the best sort of grinder is integral to keeping top quality and performance in coffee production, making it important for services to spend in top notch burr mills for optimal outcomes.

Key Attributes to Think About

Choosing a commercial coffee grinder needs careful consideration of several vital attributes that can substantially influence both efficiency and the total coffee experience. One of the main elements to evaluate is the grinding device. Burr mills are normally chosen over blade grinders, as they offer a consistent work size, which is vital for ideal removal and flavor.

Another vital function is the grinder's capability. Depending on the volume of coffee you need to process, choose a design that can manage your demands without compromising rate or top quality. Additionally, consider the work settings provided. A functional grinder with several setups allows you to tailor the grind size to various developing approaches, boosting the coffee's taste account.

Examine the mill's sound level, particularly in an active coffee shop or production setting, where excessive noise can be disruptive. Spending in a grinder that stabilizes these functions can greatly improve both operational performance and the top quality of the coffee offered.

Optimizing Grinding Process

To achieve the best results in coffee preparation, optimizing the grinding procedure is essential. The grind size considerably affects removal, flavor, and overall high quality of the made coffee.

In addition, keeping track of the grinding rate can optimize the procedure. Slower grinding frequently generates much less warmth, preserving fragile flavors and aromas. On the other hand, quicker grinding might generate extreme heat, negatively affecting the coffee's high quality.

Maintenance and Treatment Tips

Proper maintenance and care of industrial coffee grinders are necessary for ensuring optimal efficiency and long life. Regular cleaning is the structure of maintenance; deposit buildup can influence taste and grinding performance. It is suggested to clean up the grinder after each usage, cleaning down the outside and removing any type of coffee grounds from the burrs.

In addition, examine the grinding burrs for wear and tear. Boring burrs can jeopardize work uniformity, so they need to be replaced as required. Industrial Coffee Grinder. Occasionally adjusting the mill is also vital, as this keeps the wanted work dimension for numerous brewing approaches

Lubrication of relocating components should be carried out according to the maker's requirements, as this reduces rubbing and lengthens the life of the tools. It is important to use food-grade lubricating substances to ensure security and conformity with health and wellness guidelines.

Finally, keep the grinder in a dry and steady environment to stop rust and rust. By sticking to these upkeep and care suggestions, drivers can improve the efficiency of their industrial coffee grinders while guaranteeing premium outcome and expanded operational life.

Return on Investment Evaluation

Evaluating the return on investment (ROI) for industrial coffee mills is critical for services seeking to maximize their coffee manufacturing capacities. A thorough ROI analysis aids identify the economic feasibility of spending in high-quality grinders, permitting organizations to evaluate the initial costs versus potential gains.

To conduct a comprehensive ROI evaluation, companies ought to take into consideration numerous check my site vital factors. Assess the acquisition price of the mill, including setup and any kind of needed adjustments to existing framework. Next, compute operational costs, consisting of power usage, maintenance expenses, and labor effectiveness improvements. High-performance grinders typically result in reduced grinding time and increased throughput, which can significantly boost performance.

In addition, take into consideration the effect on product high quality. Industrial Coffee Grinder. Superior mills generate a more regular grind size, which can improve flavor accounts and customer complete satisfaction, eventually driving sales. By increasing the high quality of the last item, companies can justify greater rates, bring about try this site raised revenue

Conclusion

In recap, a commercial coffee mill plays a pivotal duty in improving both efficiency and item high quality within coffee production. By choosing high-quality burr grinders furnished with vital features such as adjustable work settings and long lasting building, services can ensure ideal taste removal. In addition, normal maintenance is vital for maintaining grinder performance and making the most of customer satisfaction. Ultimately, the calculated financial investment in a dependable grinder contributes considerably to improved earnings and competition in the coffee market.

In the competitive landscape of coffee production, selecting the right commercial coffee grinder plays a crucial role in enhancing both efficiency and item high quality. The two primary kinds of grinders are blade grinders and burr grinders. Within the burr mill group, there are flat burr grinders and conical burr mills, each with its benefits. Burr mills are typically liked over blade grinders, as they give a consistent grind size, which is critical for optimum removal and flavor.

In recap, a commercial coffee mill plays a critical duty in boosting both efficiency and product top quality within coffee production.

Comments on “How an Industrial Coffee Grinder Can Enhance Your Coffee Quality”